• BRUSHLESS

AC • DIRECT

DRIVE ROTARY • DC

SERVO • FRAMELESS

SERVO •

• SERVO

AMPLIFIERS & DRIVES •

•top

of page•

• BRUSHLESS

AC SERVO MOTORS

• Standard

NEMA Frames: NEMA 17 to 56

• Standard Metric Frames

• Speeds up to 12,000 RPM

• Continuous Torque's to 478 in-lb

• Peak Torque's to 1,505 in-lb

• Standard Encoder or Resolver Feedbacks

• Connection Options: Flying Leads, IP65 Connectors,

MS Connectors

• OPtional Brake

• Custom Shafting & Cabling Available

|

|

|

•top

of page•

• DIRECT

DRIVE ROTARY SERVO MOTORS

BENEFITS

• Elimination of Gearboxes: Zero maintenance, smooth

velocity & Quiet

• Elimination of Belts: Zero Maintenance & Higher

bandwidth

• Large through bore: Run process fluids, pneumatics

and electrical through center of motor

• Speeds up to 800 rpm

• High position resolution: Up to 2 million counts/rev.,

Repeatability down to +/- 0.62 arc.sec

• Peak torque up to 990 lb-ft

• Axial loading up to 12,700 lbs

• Moment loading up to 472 lb-ft

|

|

| Model No. |

Continuous Torque lb-ft. |

Peak Torque lb-ft. |

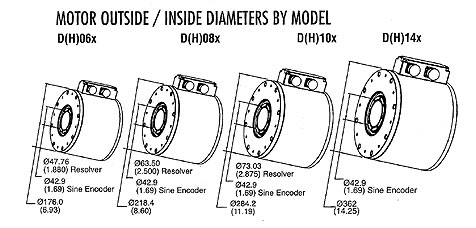

| D(H) 06X |

14.5 |

38.0 |

| D(H) 08X |

41.3 |

130 |

| D(H) 10X |

100 |

370 |

| D(H) 14X |

250 |

989 |

|

|

•top

of page•

• DC

SERVO MOTORS

• Speeds

to 20,000 RPM

• Sizes from less than 2" to 8" Diameters

• Torque to 50 lb-in

• Feedback Options: Tachometer or Encoder

• Mounting: NEMA or Metric

• Optional shaft & cable configurations

|

|

|

•top

of page•

• FRAMELESS

SERVO MOTORS

BRUSHLESS

FRAMELESS SERVO MOTORS

RBE series brushless motors provide a wide range

of flexible motor solutions for frameless direct

drive rotary motor applications.

•

10 frame sizes from 0.84" (21.3mm) to 9.41" (239mm)

outside diameter

• Continuous torque range rom .09 lb-in (.01 Nm)

to 336.30 lb-in (38 Nm)

• Peak torque range from 2.7 lb-in (.03Nm) to 1,770

lb-in (200 Nm)

• Speeds up to 35,000 RPM

• Optional integral Hall sensors

|

|

|

BRUSHED

FRAMELESS SERVO MOTORS

Direct Drive DC torque motors provide high stall torque for positioning

systems. Ideal for high torque at low speeds for speed control systems

and optimum torque at high speed for positioning, rate, or tensioning

systems.

• Frame

sizes range from 1.13" (28.7mm) to 42" (1067mm)

• Peak torque range from .177 lb-in (.02 Nm) to

36,019 lb-in (4070 Nm)

• Optional housed design allows for DC tachometers,

resolvers, encoders and shaft configurations

|

|

|

•top

of page•

• SERVO

AMPLIFIERS & DRIVES

ACCELUS

SINUSOIDAL AMPLIFIER

• Field

oriented control for optimal Speed/Torque capability

•

Auto-pahsing & auto-tuning simplify Commissioning

• Position, velocity and torque modes

• AZ Brushless and DC brush control

• Voltage: 20 to 180VDC

• Current ranges from 3A cont. to 36A peak

• Feedback: Incremental Encoder w/halls

• Discrete Input Functions: Enable, Limits, Motor Sensors

• Housing: Panel or Card

• Low Cost

|

|

|

SERVOSTAR

PD SERVO DRIVES

• Input

Voltages: 16 to 100VDC

• Output currents from 5A cont. to 20A peak

• Feedback: Incremental Encoder, Resolver, Sine Encoder,

or halls

• Auxiliary encoder feedback, use for Dual loop or

Master/Slave operation

• Configurable I/O: 3-digital inputs & 1-digital output

• Operational Modes: Torque, VElocity, Pulse following,

gearing from quad encoder input & position control

• Low Cost

|

|

|

S200

SERIES SERVO DRIVES

• Torque

or Velocity Mode

• Voltage Inputs: 20-90VDC or 120/240VAC

• Current Ranges from 1A cont. to 18A peak

• High resolution feedback (24 bit)

• Current Loop Bandwidth to 5 kHz

• Velocity Loop Bandwidth to 800 Hz

• Optically isolated I/)

• Easy tuning

• OPtional: Indexing, CANopen, or DeviceNet

• Compact: 1.1" x 6" x 3.9" (DC Model)

2.2" x 6.9"

x 5.2" (AC Model)

• Low Cost

|

|

|

|